Profile

Alpha Labs, Inc. is an international certification group based on USA, China, Taiwan and Europe companies, working in the area of testing and certification of electrical products for more than 25 years. In addition, we provide a turnkey operation in product integration of manufacturing, medical, industrial and information technology sectors.

Alpha Labs, Inc. has built a solid foundation of product testing and certification, capitalizing on the skills and experience of its engineering and management team. We has undergone a transformation from a testing and certification company, to a service integrator company with the means to deliver its service to the global market. Our detail-oriented team is committed to achieving excellence in our services during the course of business.

Years of experience in product evaluation, testing and certification undoubtedly gives us the upper hand in understanding and executing even the most complex projects in a professional manner.

Alpha Labs, Inc. has a very clear focus; to provide the necessary engineering tools to assist companies to get their product complies to the requirement of UL, CSA, IEC and BSI standards. We cover all facets of electrical machinery disciplines to solve your technical needs and exceed your expectations.

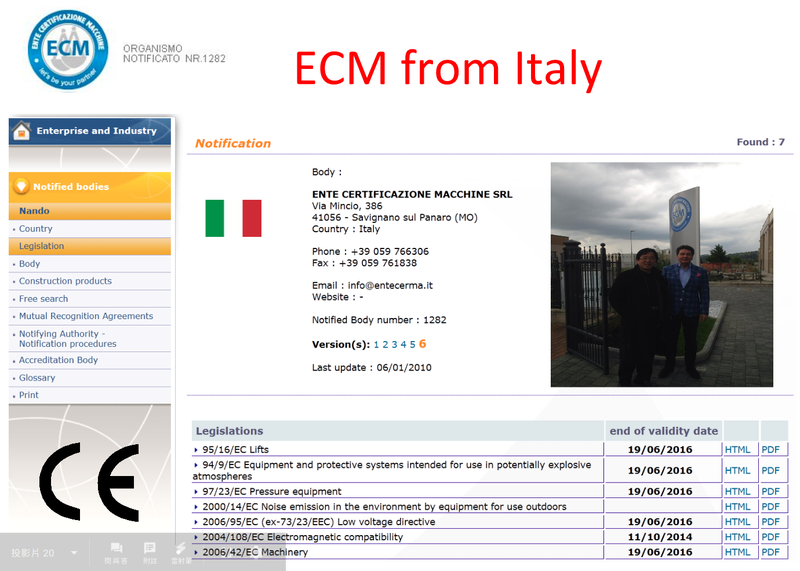

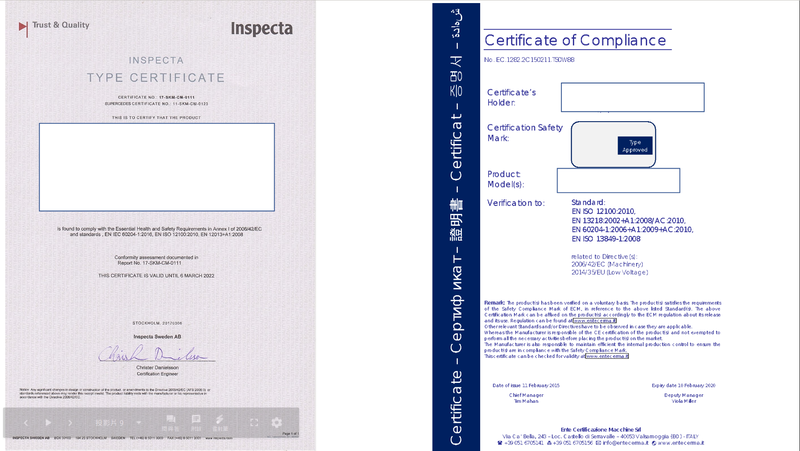

Italy ECM Notify Body ( NB code: 1282 ) be accredited by Europe Union. ECM Italy can issue the CE certificate for MD, LVD , EMC , PED , MDD and GS Mark of machinery and electrical products. The EU authorized representative service also be one of the service in EU Europe.

Belay USA , QAI USA and QAI Canada are all professional competent body for SEMI S2/S8 , OSHA USA UL and Canada SCC CSA, We can support NRTL FES Labeling Service by UL stadnards and SCC Special Inspection Service by CSA standards. Let tool vendor and buyer have the machiney comply to USA and Canada regulatory for EHS machine safety.

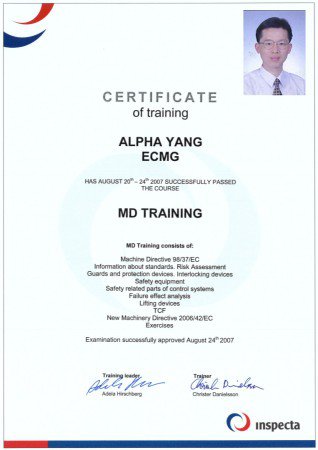

About Inspecta ( NB Code : 0409 )

Inspecta provides Inspections, Testing, Certification, Technical Consultancy and Training services. We are the leading company in the Nordic area within our business. We have offices in eight countries; Finland, Sweden, Norway, Denmark, Latvia, Estonia, Lithuania and Poland. We employ more than 1,500 people and have an annual turnover of 176 M€.

About us

The Alpha Labs, Inc. team has a combined 20 years of experience in the Product testing and Certification, SEMI S2 evaluation, CE Compliance and Design consultation business.

Mr. Hellstrom has over 27 years of design and safety engineering experience which he applies to system safety and hazard analysis. He has over 20 years experience in the safety analysis and certification of every type of semiconductor and photovoltaic manufacturing equipment to industry and SEMI Standards. He specializes in mechanical hazards analysis, seismic analysis, hazardous waste tank assessments, and analysis of chemical distribution systems including analysis of equipment for installation Class 1, Division 2 locations. He also supports electrical certification and field labeling of equipment. His analyses techniques experience include Fault Tree, HAZOP, and Failure Mode and Effects Analysis (FMEA). Mr. Hellstrom is a certified Aboveground Tank Inspector per Steel Tank Institute Standard SP001 and a Registered Mechanical Engineer in the State of California.

Mr. Alpha Yang is currently the International Project Manager for the testing and Certification of Engineering Services.. He has worked for the Taiwan and USA Labs in industrial safety and code compliance. Alpha has performed a number of product testing and certification of electrical machinery in USA/EU/CHINA and outside the USA/EU/CHINA. Alpha holds a Master Degree (MSEE) and Study for PhD Degree from the Tatung University of Taiwan in Electrical engineering.

Mr. Robert Lin has over 10 years experience in product evaluation of electrical equipment in the USA, Canada, and Europe. Mr. Robert Lin is currently the Managing Director for Belay Engineering Service that is performing product evaluation to national and international standards. In addition, he manages the SEMI S2 and CE projects for the US, Europe and Asia markets. He holds an electrical engineering degree (BSEE) from the Engineering and System Science Department, National Tsing Hua University, Taiwan.

Testing & Certification

In summary the CE Marking evaluation will include:

-

Evaluation:

-

Machinery Directive (2006/42/EC)

-

Low Voltage Directive (2014/35/EU)

-

EMC Directive (2014/30/EU)

-

Pressure PED Directive (2014/68/EU)

-

Report

-

Technical Construction File (TCF)

-

Certificate of Compliance

Low Voltage Directive CE Marking evaluation to include the following:

-

A comprehensive evaluation of the equipment to the Low Voltage Directive utilizing harmonized standard EN 60204-1 or EN 61010, as appropriate.

-

An informal Mechanical evaluation utilizing Annex I of the Machinery Directive.

-

Internal Technical Peer Review.

-

Closing meeting to verbally review list of discrepancy issues at the end of the on-site evaluation.

-

An electronic copy of Bullet List Discrepancy Report issued within 3 working days following the On-site evaluation.

-

An electronic copy of Final Evaluation Report issued within 14 working days following receipt of satisfactory responses to the Bullet List Discrepancy Report.

Machinery Directive CE Marking evaluation to include the following:

-

A comprehensive evaluation of the equipment to the Machinery Directive utilizing appropriate harmonized standards (e.g., ISO 12100-1, ISO 12100-2, EN13850, EN13849, EN12100:2010, EN982, EN983, and EN60204-1 or EN61010).

-

Internal Technical Peer Review.

-

Closing meeting to verbally review list of discrepancy issues at the end of the on-site evaluation.

-

An electronic copy of Bullet List Discrepancy Report issued within 3 working days following the On-site evaluation.

-

An electronic copy of Final Evaluation Report issued within 14 working days following receipt of satisfactory responses to the Bullet List Discrepancy Report.

ALPHA LAB, INC. and OSHA NRTL/FEB Partner performs on-site field inspection, evaluation

and labeling of electrical products that did not have a certification

mark required by NRTL (Nationally Recognized Testing Laboratory). We

have done more than 1000 field inspection over the span of 20 years in

different product category that includes industrial machinery,

laboratory equipment, medical diagnostic equipment, laser, sheet metal

fabrication equipment, robotics, wind and solar and wind energy

systems.

ALPHA LAB, INC. perform inspection, evaluation and labeling of electrical products.

-

Evaluation to relevant UL, CSA, ANSI, ASME and NFPA standards

-

In Canada, SPE-1000 Special Inspections Evaluation to NEC (National Electric Code) and CEC (California Energy Commission)

-

Requirements Evaluation to relevant OSHA safety requirements Adherence to the recommended practice and procedures for unlabeled electrical equipment evaluation developed by the American Council for Electrical Safety (ACES)

-

Full knowledge and experience with U.S. and foreign equipment

-

Highly competent experienced engineers in all aspect of product testing and evaluation of electrical products.

-

In the USA, our Belay Engineering local testing laboratories recognized by the local Authority Having Jurisdiction are qualified to offer Field Evaluation services. Belay Engineering is recognized in several state and local jurisdictions. The technical requirements used to evaluate products for the US market consist of the applicable parts of the National Electrical Code (NEC) and other requirements specified by the AHJ. Complying products are labeled using the NRTL label shown.

-

ALPHA LAB, INC. with Belay Engineering - USA Partner is accredited by states, counties and cities in the USA to perform Electrical Evaluation, Testing, Inspection and Certification of electrical machinery to national standards that acceptable to the jurisdictions.

The SEMI S2/S26 guideline defines minimum performance-based safety

requirements. The scope of these requirements covers potential health

and safety hazards such as mechanical, electrical, chemical, ionizing

and non-ionizing radiation, seismic, ventilation, environmental and

ergonomics. There are many additional SEMI guidelines that are

referenced by or otherwise support SEMI S2/S26. A partial list appears

below.

S2 Evaluation to SEMI® Guidelines

Comprised of 20 basic elements:

-

Documents Provided to User

-

Hazard Warning Labels

-

Safety Interlock Systems

-

Emergency Shutdown

-

Electrical Design

-

Fire Risk and Protection

-

Heated Chemical Baths

-

Ergonomics and Human Factors

-

Hazardous Energy Isolation

-

Mechanical Design Seismic Protection

-

Automated Material Handlings

-

Environmental Considerations

-

Exhaust Ventilation

-

Chemicals

-

Ionizing Radiation

-

Non-ionizing Radiation and Fields

-

Lasers

-

Sound Pressure Level

-

Manual Review (Installation, Operation, Maintenance)

Machinery safety in Brazil - Norma Regulamentadora NR-12

NR-12 is a local machinery safety directive, compliance with which is mandatory. It was originally enacted in 1978, but it wasn't until the 5th revision in December 2010 that really comprehensive machinery safety requirements were defined. In principle NR-12 is only freely available in Brazilian Portuguese. However, an unofficial English translation of the 2010 edition does exist, although it should only be applied in context with the original language version. The structure, content and safety requirements of NR-12 are heavily based on Annex I of the EuropeanMachinery Directive MD 2006/42/EC, but are not absolutely identical. Unlike the MD, NR-12 is aimed directly at Brazilian machine operators and not at machine manufacturers. Also, unlike the MD, NR-12 applies to both new and used machinery.

All public and private sector employees as well as employees registered with CLT must abide by these regulations. NR-12 was drawn up by representatives of the Brazilian federal government along with representatives of employers and employees (unions). The aim was to guarantee that safety requirements on new and used machinery would meet the international safety standard.

Aim of NR-12

The main aim of NR-12 is to ensure that a new generation of machinery is inherently safe in all life phases, from transportation to commissioning, use, maintenance and finally disposal. NR-12 also includes measures for adapting existing machinery. The standard also defines requirements for planned, preventive maintenance. There are also requirements for the scrapping of old machinery, to prevent the sale of obsolete machinery that is ill-equipped in terms of the safety regulations. The regulations now require a machine to be equipped to meet the current safety standards before it is resold. Machine manufacturers must know and also implement the specific requirements of NR-12 in order to prevent problems with the operator. Technical documentation in Brazilian Portuguese is one critical factor.

From the beginning, KOSHA played a significant role preventing occupational hazards, accidents, and diseases from worksites. Speaking of the businesses, first we cannot help but talk about the development and spread of prevention technologies, support to educate workers visiting worksites, as well as, analysis and inspection of facilities that are likely to bring the danger or harmfulness, since KOSHA was released.

KOSHA focused on activities such as safety diagnoses, guiding new technologies, and education for workers concerned with safety and health that workers and workplaces were asking for in the beginning. It took two years for KOSHA to develop and spread the systematic ways such as visiting worksites and analyzing causes or doing epidemiology research to find the cause of industrial accidents.

KOSHA focused on activities such as safety diagnoses, guiding new technologies, and education for workers concerned with safety and health that workers and workplaces were asking for in the beginning. It took two years for KOSHA to develop and spread the systematic ways such as visiting worksites and analyzing causes or doing epidemiology research to find the cause of industrial accidents.

It was in 1995 that KOSHA was absorbed in trying to reduce the rate of occupational accidents because the campaign for safety culture at workplaces was widespread all over the country. Therefore, KOSHA started to take an action that put aside the some amount of money to prevent those accidents in small and medium businesses that were blamed for occupying the 73.5% of total occupational disasters. Also, the rate of industrial accidents was plunged under 1% that is the sign of getting into the developed country.

Certificate Query

Please input Certificate No. to query Certificate